Futurecity has teamed up with This is Engineering and the Royal Academy of Engineering to celebrate This is Engineering Day.

In 2018, the Royal Academy of Engineering, in partnership with EngineeringUK, launched a campaign to change perceptions and encourage young people to pursue a career in engineering.

As public art curators and the first art partners of #ThisIsEngineering, we wanted to highlight the important role that engineers play in the creation of major sculptural artworks, bringing this often unseen side of engineering to the campaign.

We have compiled the top three facts and images from the engineers behind five major artworks curated by Futurecity, in order to give insight into the complex and fascinating process for each of these sculptures.

Bicameral

‘Bicameral’ by Conrad Shawcross RA is an 8m tall sculpture made out of 693 component parts entirely without welding, engineered by Structure Workshop.

Location: Belgravia, London | Curator: Futurecity | Client: Qatari Diar

FACT 1: Bicameral is a branching structure fabricated in aluminium. The geometry is heavily rule-based and was developed using parametric software. This computational approach allowed the complex form to be tested at different scales and using varying proportions before the final geometry was decided.

FACT 2: The structure is entirely dry assembled using a slotted joint and orthogonal pin system that develops very high strength connections. The 8 generations were waterjet cut out of sheet material before being milled and drilled to develop the necessary holes and tolerance fit. The parts were then anodised in blue to provide long term protection to the surface.

Column

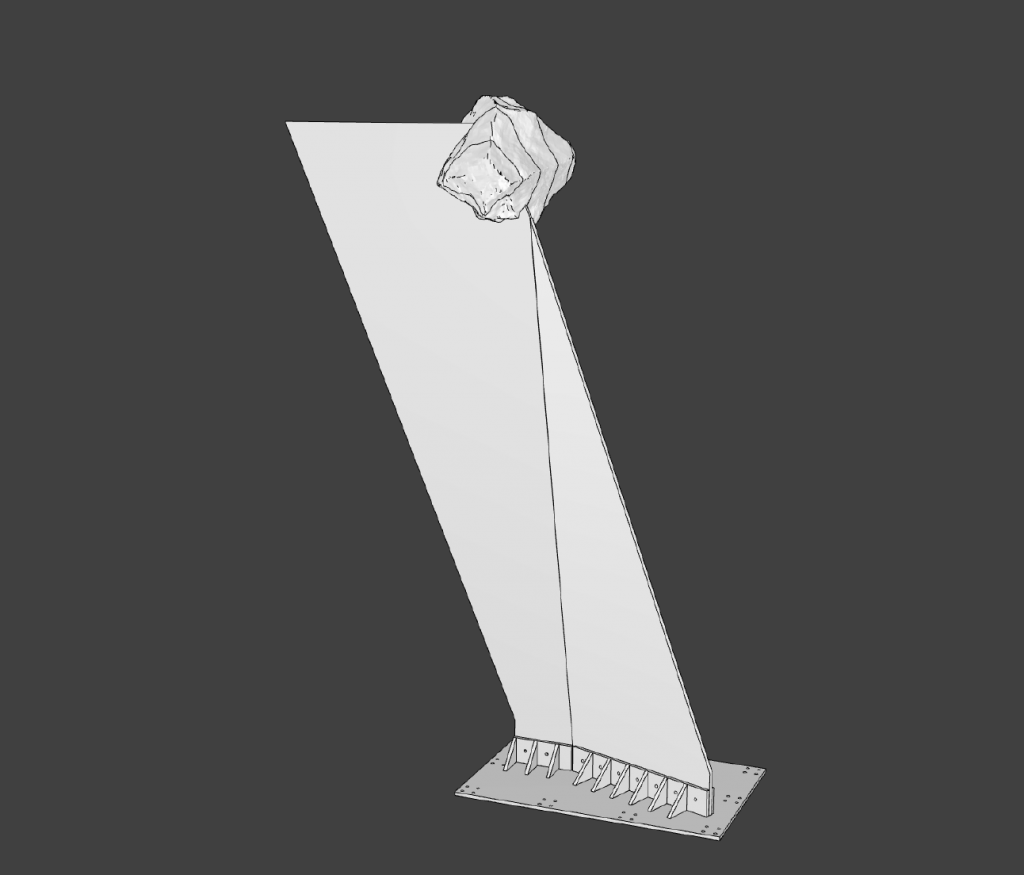

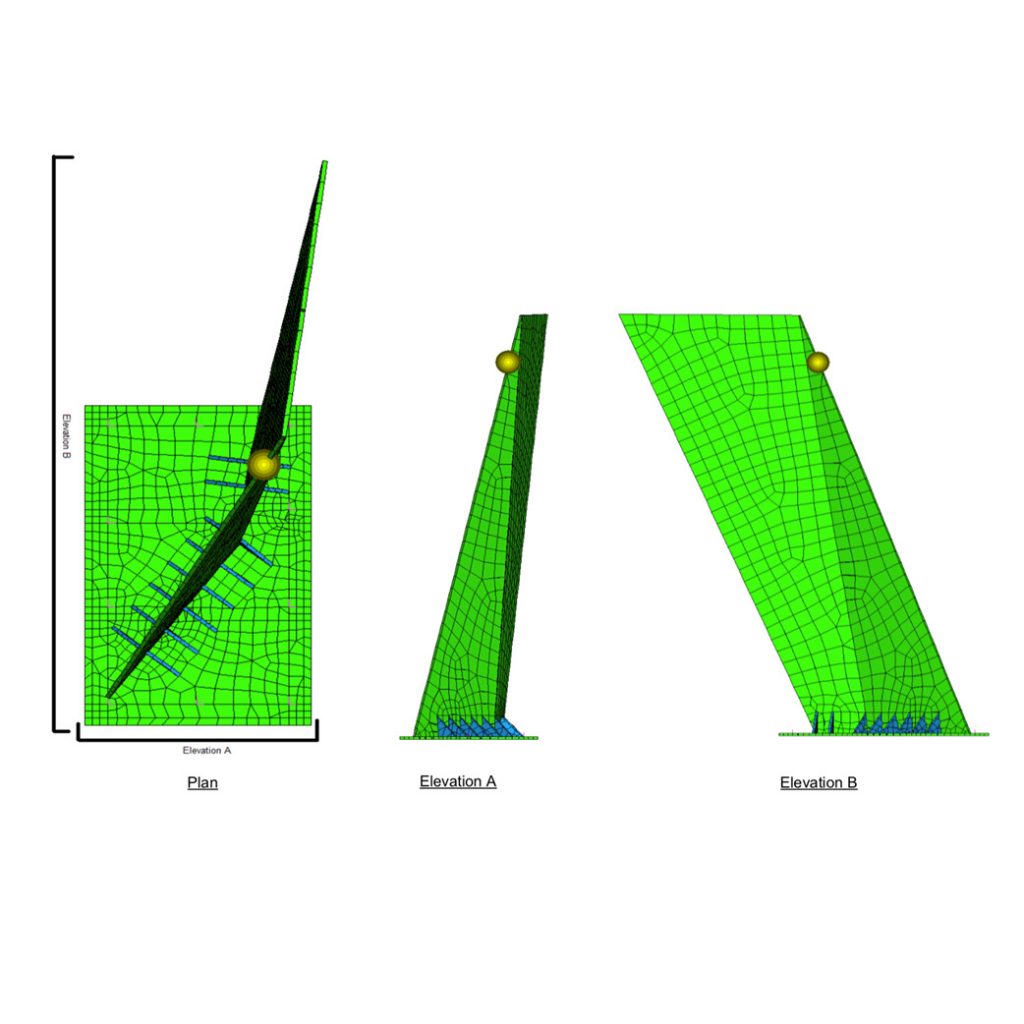

‘Column’ by Studio Swine is a 5.3m sculpture consisting of a large reflective aluminum rock perched on a rusted corten steel sheet, engineered by Millimetre and Structure Workshop.

Location: Islington, London | Curator: Futurecity | Client: Mount Anvil

FACT 1: The Weathering steel [Patinax 355] ‘blade’ is 35mm thick and is formed from 2 waterjet cut forms. The baseplate and webs have been cut from a single sheet of 30mm Corten Steel.

FACT 2: The ‘rock’ was cast in 4 parts from an Aluminium alloy LM25, then reassembled into 2 parts with joint lines fettled and blended prior to polishing. Plates have been welded into the 2 parts of the ‘rock’, with studs protruding allowing for the sequential fixing of both parts to the ‘blade’. A capped hole in the top of the ‘rock’ allowing access to the clamp plates and fixings.

FACT 3: The location of the artwork with locally potentially high windspeeds due to the funnelling of the wind between the surrounding buildings. A qualitive flutter study was undertaken and the findings considered within the design, initial modelling and calculations meant the thickness of the Weathering steel and weight of the rock needed to be re considered. Indeed the weight of the rock was increased [to act as a damper] to reduce the potential for high winds to induce certain frequencies/vibrations.

Slipstream

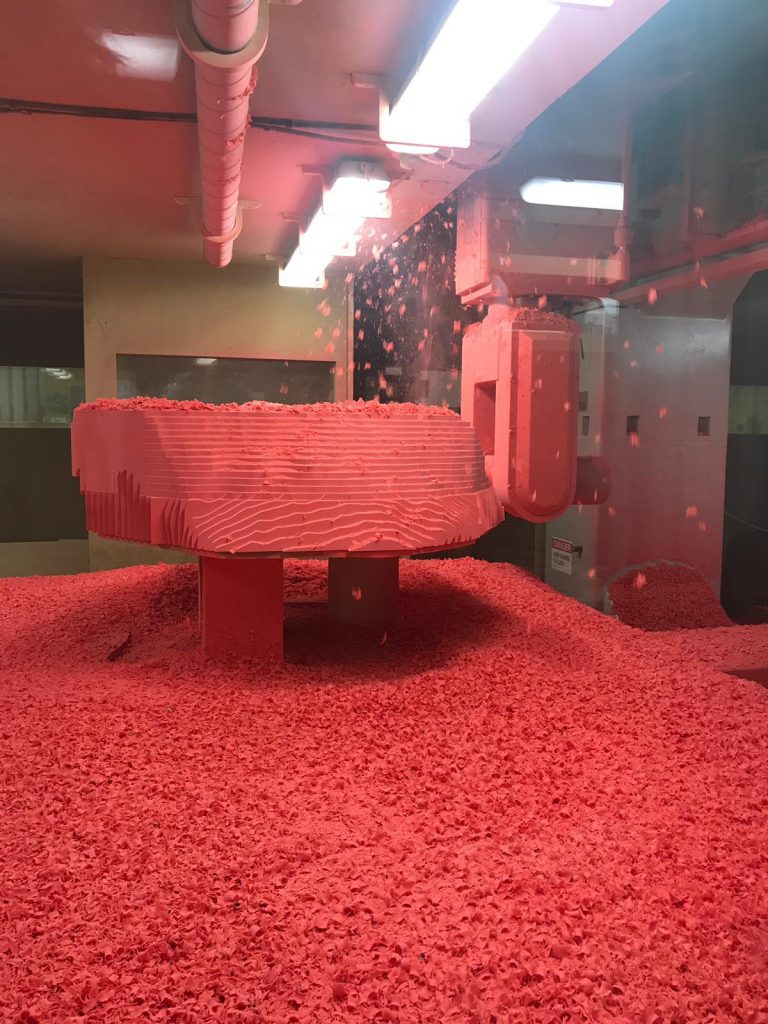

‘Slipstream’ by Richard Wilson RA is a 70m long imagined flight path of the ‘Edge 540’ in a sculptural form, engineered by Price & Myers.

Location: Terminal 2, Heathrow Airport | Curator: Futurecity | Client: Heathrow Airport Holdings Ltd

FACT 1: The shape of Slipstream was sculpted and refined through 49 prototype models before the final form was established. We engineered a form that balanced Richard Wilson’s artistic vision with the engineering challenges of supporting a 70m long, 77 tonne sculpture high in the air, on only four columns.

FACT 2: The undulating surface of the sculpture is made from aluminium sheets and rivets but under this skin is a plywood and steel skeleton that both gives rigid form to the artwork and allows it to span the 18m gap between the supporting columns. The skeleton is precisely made with thousands of parts slotting together to give the piece its strength.

FACT 3: Every part of the skin and structural skeleton is a unique shape. We designed and engineered over 35,000 different timber and steel pieces to fit together like a three-dimensional jigsaw puzzle. Digital design, scripting and robotic fabrication made this possible. To minimise the sculpture’s ecological impact, each component of the interlocking structure is engineered to be light and small, using as little material as possible.

Optic Cloak

‘Optic Cloak’ by Conrad Shawcross RA is a 50m ‘moiré camouflage effect’ sculptural intervention, engineered by Structure Workshop.

Location: Greenwich Peninsula | Curator: Futurecity | Client: Knight Dragon

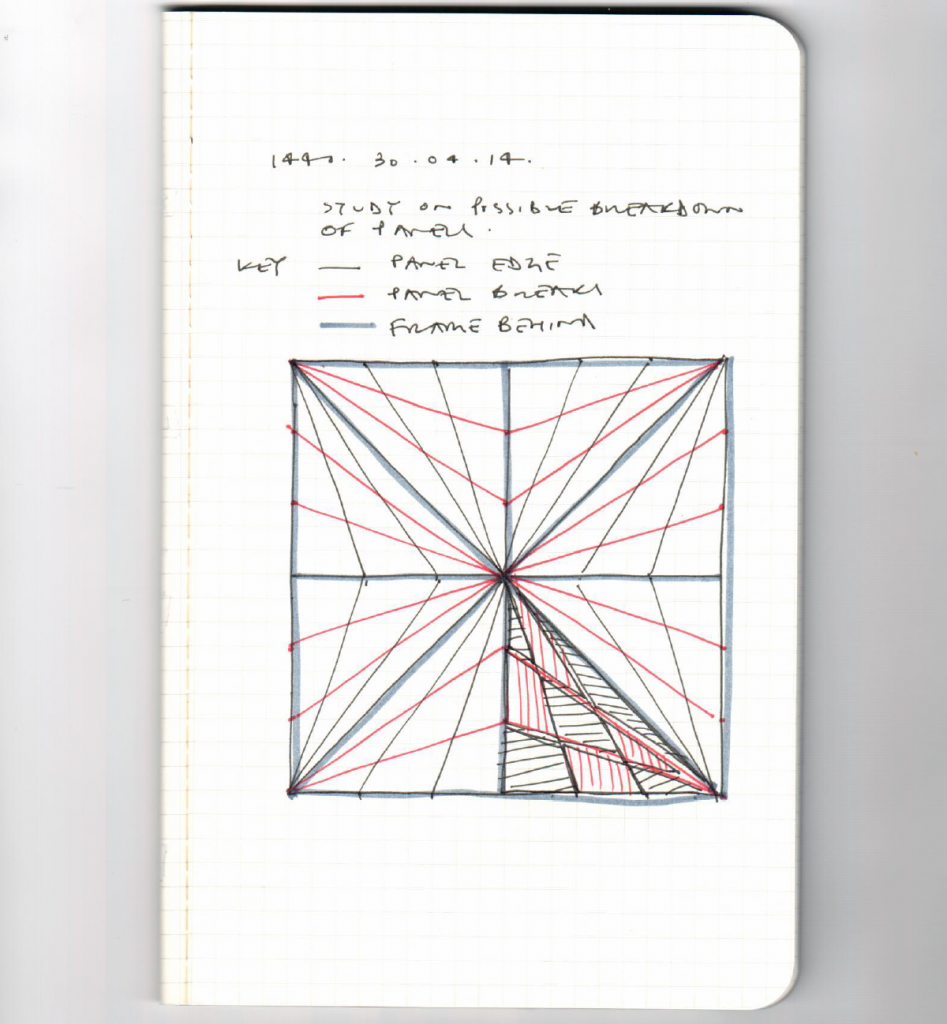

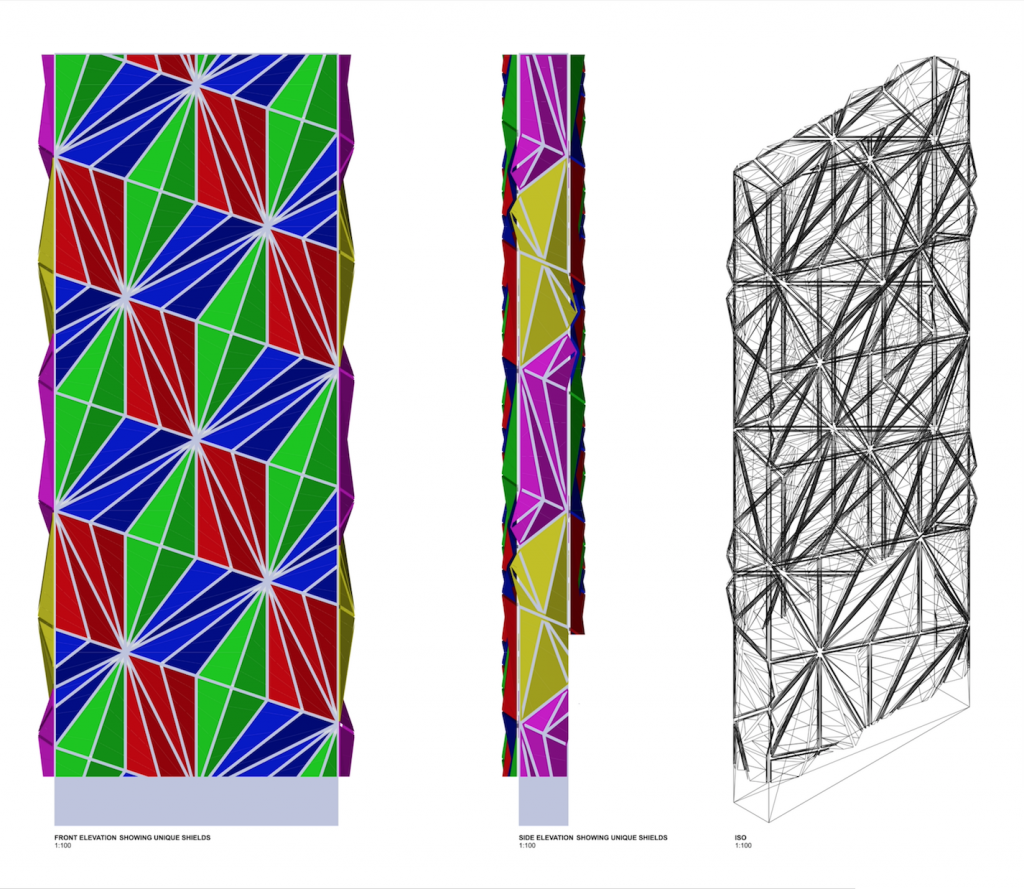

FACT 1: The geometry of the tower is developed from a square folded pattern, rotated against the cuboid shape of the flue tower. The geometry is repeated on the reverse but handed to generate complex moire patterns when seen in silhouette with the light behind. The side panels are the result of study to resolve the front and back geometry with the most repeat i.e. least number of unique panels.

FACT 2: The structural frame aligns with the cladding pattern to maximise the amount of light passing through the tower. The tower itself is very thin for its height and this required a very strong frame to ensure that it was stiff enough to avoid loading or damaging the flues in high winds.

FACT 3: The aluminium cladding panels are isolated from the galvanised steel tower using nylon spacers. This avoids bimetallic action corroding the steel work locally around the fixings.

Infinity Blue

‘Infinity Blue’ by Studio Swine is an 8m tall breathing sculpture, engineered by Structure Workshop.

Location: Eden Project | Curator: Futurecity | Client: Eden Project

FACT 1: The cladding panels are made from a glazed earthenware ceramic that was typically used in the 19th and 20th century on pubs, tube stations and public buildings, such as the Natural History Museum.

FACT 2: In this application the panels were hung from each corner using resin anchored fixings, from which were load-tested to demonstrate their capacity.

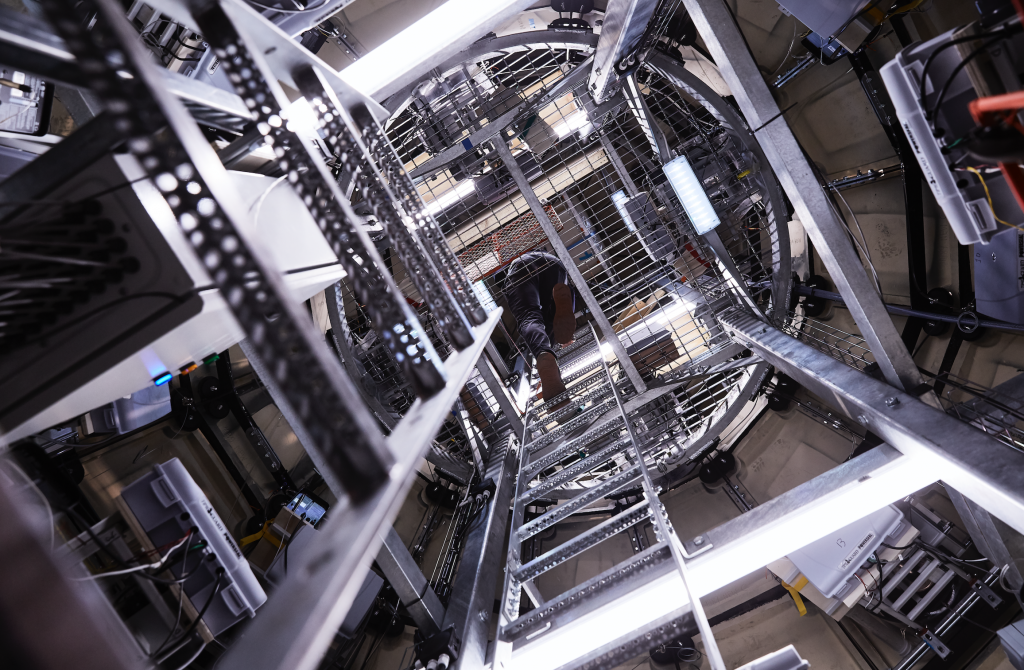

FACT 3: The support structure was designed to provide fixing points for the panels, as well as to provide maintenance access to all the ‘smoke’ machines that blow rings across the exhibition hall.

Me. Here. Now

‘Me. Here. Now’ by Mark Titchner is a sculpture consisting of three polished stainless steel domes suspended from the ceiling, engineered by Collins Winning.

Location: Stainer Street, London Bridge Station | Curator: Futurecity | Client: Network Rail

FACT 1: The black dots you see are anti vibration pads to stop the stainless steel moving.

FACT 2: Every stainless steel plate is unique with its print pattern.

FACT 3: Every panel has its own unique number.

Check the This is Engineering website to find out more:

https://www.thisisengineering.org.uk/